Construction Vibration and Noise in Laboratories and Healthcare Facilities

A Risk-Based Approach to Protecting Scientific, Medical, and R&D Operations

Impacts Management and Monitoring

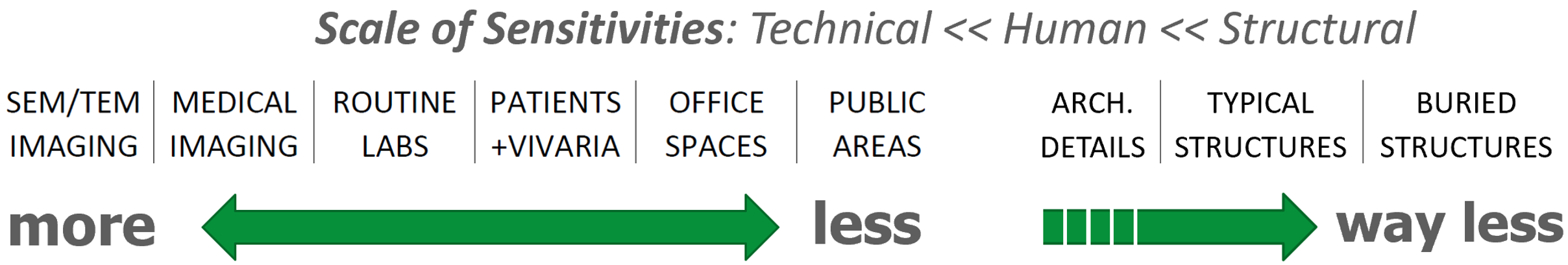

Laboratories and healthcare facilities are uniquely sensitive environments. Precision instruments, delicate experiments, medical imaging suites, and tightly controlled conditions mean that even modest disturbances from nearby construction can jeopardize research quality, clinical operations, and create significant financial or reputational risks. While human annoyance and vibration-induced damage are widely acknowledged, technical sensitivities in laboratory, healthcare, and R&D settings demand a more rigorous, customized approach.

Vibrasure’s construction impacts management services integrate risk assessments, lab-focused monitoring instrumentation, and real-time alerting/data delivery to ensure that science and medicine continue uninterrupted, even when construction is close at hand.

Read on for insights into:

Why Construction Vibrations Are Different in Labs and Healthcare Facilities

A Risk-Based Framework for Impact Assessment

Lab-Grade Monitoring: Beyond Structural Protection

Reporting, Documentation, and Long-Term Value

Protecting Science and Medicine Through Precision Monitoring

Why Construction Vibrations Are Different in Labs and Healthcare Facilities

Construction on a research or medical campus is rarely optional. Expansions, retrofits, and infrastructure projects are the lifeblood of keeping facilities up to date. But when these projects take place alongside active laboratories or healthcare suites, the stakes change dramatically. Vibrations from excavation, drilling, or even routine shoring work ripple through building structures and foundations, potentially affecting sensitive spaces in ways that humans cannot perceive.

This sensitivity is not confined to only the most advanced nanotechnology suites. While instruments like electron microscopes, lithography tools, and scanning probe systems operate at tolerances far below human thresholds, they are not the only ones at risk. Healthcare facilities face similar challenges: imaging equipment such as MRI, PET, and CT scanners are vulnerable to vibration and acoustic disturbances, which can degrade scan quality or interrupt patient care. Animal facilities and vivariums can also be disrupted by both vibration and noise, with impacts on welfare, breeding cycles, and research outcomes. Even “typical” laboratory activities – such as synthesis, cell culture, or routine imaging – can be destabilized by unexpected disturbances.

Key consequences of uncontrolled construction vibration:

Disruption of data collection or calibration drift in precision instruments.

Scan artifacts, poor image quality, or interruptions to medical and nanoscale imaging.

Stress, behavioral changes, or reduced reproducibility in animal facilities.

Compromised / confounded results in routine laboratory workflows.

Irrecoverable loss of samples or data, leading to wasted research time.

Reputational, recruitment, and even financial damage for institutions.

A Risk-Based Framework for Impact Assessment

Addressing these challenges begins before the first hammer falls. Effective monitoring starts with establishing a clear baseline: measuring the existing background vibration environment and listening closely to users about what is at stake. Interviews with principal investigators, medical imaging staff, surveys of equipment vendors, and baseline studies conducted in advance can all help build a picture of what “normal life” looks like, both qualitatively and quantitatively.

From there, risk assessment becomes an exercise in context. Total risk isn’t just about sensitivities; it’s also about the potential consequences of impacts. A brief spike in vibration might be little more than an annoyance in an office setting, but if it coincides with high-resolution imaging, whether in a nanotech lab or an MRI suite, it could invalidate an entire dataset or patient scan. And every so often, we encounter a program where an otherwise minor disturbance could have outsized consequences – what we refer to as the “alien autopsy problem.” Our process helps uncover these rare situations early enough to address them proactively.

Our approach combines empirical data, published criteria, construction simulations, and the perspective gained from decades of laboratory experience – insight that helps us anticipate sensitivities and risks even before they surface in the field.

Our approach to risk assessment typically includes:

Pre-construction baseline vibration surveys.

User interviews and vendor criteria reviews.

In-situ construction simulations for “real” data.

Development of project-specific criteria.

Why Construction Simulations Matter

There is no universal rule for how vibrations travel through soils and structures. While it is possible to model transmissibilities, it is usually much faster and cheaper to just measure them experimentally. Realistic impact assessments benefit from in-situ simulation testing, in which the contractor engages in a variety of representative activities – drilling, coring, or small-scale demolition – while Vibrasure monitors impacts at an array of receiver locations. These simulations reveal how energy actually propagates through the structure or across a site, providing a more accurate basis for risk assessments.

Simulations support better decision-making, especially in cases where multiple techniques or mitigations are available. In one example, an owner elected to accept short-duration, high-intensity vibrations from driven piles rather than endure months of lower-level impacts from drilling. In another case, we conducted testing to help a vivarium owner evaluate whether the impacts of construction would be more or less disruptive than relocating the animals temporarily.

Simulation data helps contractors and owners weigh these tradeoffs and confidently balance efficiency, cost, and protection.

Developing Practical Criteria

Occasionally, instrument vendors provide clear vibration criteria; other times, industry guidance like the VC Curves can be used to develop project limits. Often, explicit industry-specific or regulatory guidance is absent or vague, such as in vivariums or basic science labs with hand-built experiments. In these cases, Vibrasure can develop project-specific criteria, based on decades of experience in high-tech environments.

When available, we apply vendor specifications directly. Additionally, conversations with users (PIs, animal care staff, imaging technologists, facilities managers) help shape defensible, practical thresholds. Criteria are tailored to the specific instruments, processes, and sensitivities of nearby uses, with special attention paid to balancing adverse impacts against construction productivity.

Monitoring Almost Anything

Vibrasure’s systems are built around adaptable, open-ended data-acquisition platforms. If a transducer can produce a voltage proportional to the parameter of interest – whether it’s temperature, pressure, humidity, magnetic field strength, or another environmental variable – we can integrate it into our monitoring network.

We routinely fabricate custom circuits, sensor mounts, and enclosures to support specialized measurements, and when needed, we develop new software to manage or analyze unique data types. This flexibility makes it possible to accommodate the highly specific (and sometimes unexpected) environmental needs that sometimes arise in labs.

Lab-Grade Monitoring: Beyond Structural Protection

Conventional off-the-shelf construction monitors are designed to protect structures, not science or medicine. Laboratories and healthcare facilities require systems that measure at microscale amplitudes and across extended frequency ranges. Vibrasure’s systems are designed specifically for these environments, capable of capturing disturbances far below human perception thresholds.

This attention to detail matters because the risks extend across the full landscape: from nanotech labs with world-class imaging instruments, to healthcare facilities with active medical imaging, to vivariums housing sensitive animal colonies, and to general-purpose labs where “ordinary” activities still depend on stable, predictable conditions.

Capabilities of lab-grade monitoring systems:

High-sensitivity sensors operating at microscale amplitudes and extended frequency ranges.

Compact lunchbox-sized monitoring stations with AC power; optional backup batteries; and solar panels for outdoor stations.

Continuous 24/7 monitoring with secure remote communications; real-time alerting; and historical data availability.

Optional monitoring of other environmental parameters like noise; ultrasound; EMI / magnetic field fluctuations; underwater (hydroacoustic) noise, and more.

Real-time monitoring features:

· Automated alerts at warning and alarm thresholds.

· Tiered notifications to the right people at the right time.

· Web-based dashboards for live and historical data access.

· Immediate ability for construction teams to pause or adapt methods.

Real-Time Alerts and Proactive Response

Monitoring is only valuable if it drives timely action. Vibrasure’s systems provide automated alerts when conditions approach or exceed thresholds, with multi-tier notifications that distinguish early warnings from urgent alarms to prevent both complacency and overreaction.

Alerts can be highly customized to the needs of each facility. Thresholds may be linked so that notifications are triggered only when multiple parameters – for example, both vibration and noise – exceed limits at the same time. Derivative thresholds can also be applied, allowing the system to detect rapid fluctuations in values such as temperature or magnetic field level even when absolute levels remain within range. These capabilities ensure that alerts remain relevant, targeted, and actionable.

Real-Time and Historical Data Availability

Stakeholders can access live dashboards showing both real-time conditions and historical data for all monitored parameters. Construction teams, facilities managers, laboratory staff, and clinical teams alike have visibility into vibration, noise, and other environmental factors, enabling proactive collaboration.

Reporting, Documentation, and Long-Term Value

Construction monitoring delivers value not only during active work but also long after projects are complete. Regular reporting keeps stakeholders aligned and informed, while close-out reviews provide a defensible record of compliance. Historical data from past projects become a valuable input for future risk assessments, effectively serving as an additional form of construction simulation based on real-world experience in the same geotechnical conditions and structural environment.

Deliverables and benefits include:

Daily, weekly, or monthly reports tailored to project needs.

Close-out reports that demonstrate compliance and capture lessons learned.

Archival data that supports future renovations, dispute resolution, and research continuity.

Together, these deliverables create a durable record of site behavior that can be referenced and reapplied in future work, whether at the same building or at other sites on your campus.

Conclusion: Protecting Science and Medicine Through Precision Monitoring

Construction near laboratories and healthcare facilities is inevitable. Disruption is not. By addressing technical sensitivities, applying a risk-based philosophy, and delivering real-time, actionable insights, Vibrasure ensures that research and clinical work continue without compromise.

When the stakes include data integrity, instrument performance, patient care, or irreplaceable samples, proactive construction impacts management is not a luxury – it is essential.

Conclusion: Protecting Science and Medicine Through Precision Monitoring

Construction near laboratories and healthcare facilities is inevitable. Disruption is not. By addressing technical sensitivities, applying a risk-based philosophy, and delivering real-time, actionable insights, Vibrasure ensures that research and clinical work continue without compromise.

When the stakes include data integrity, instrument performance, patient care, or irreplaceable samples, proactive construction impacts management is not a luxury – it is essential.